Embracing the circular economy is at the heart of our long-term planning, guiding both our internal operations and external collaborations. We actively seek partnerships to co-develop solutions that lower emissions, manage waste efficiently, and comply with evolving sustainability regulations.

Whether you need LCA (Life Cycle Analysis) or EPD (Environmental Product Declaration) data to calculate your carbon footprint, want to close the loop with circular solutions, or aim to reduce reliance on virgin materials, we’re ready to support your goals with practical expertise and concrete initiatives.

Distriplast offers product ranges that incorporate recycled polypropylene - all verified by LNE.

Over half of our PP corrugated sheet production involves some form of reground PP or recycled content, with specific formulations.

By integrating post-industrial (PIR) or post-consumer materials, we cut our carbon footprint and provide high-quality, durable boards that customers can confidently reuse. The third-party certification ensures our declared percentages of recycled plastics are accurate and consistently applied.

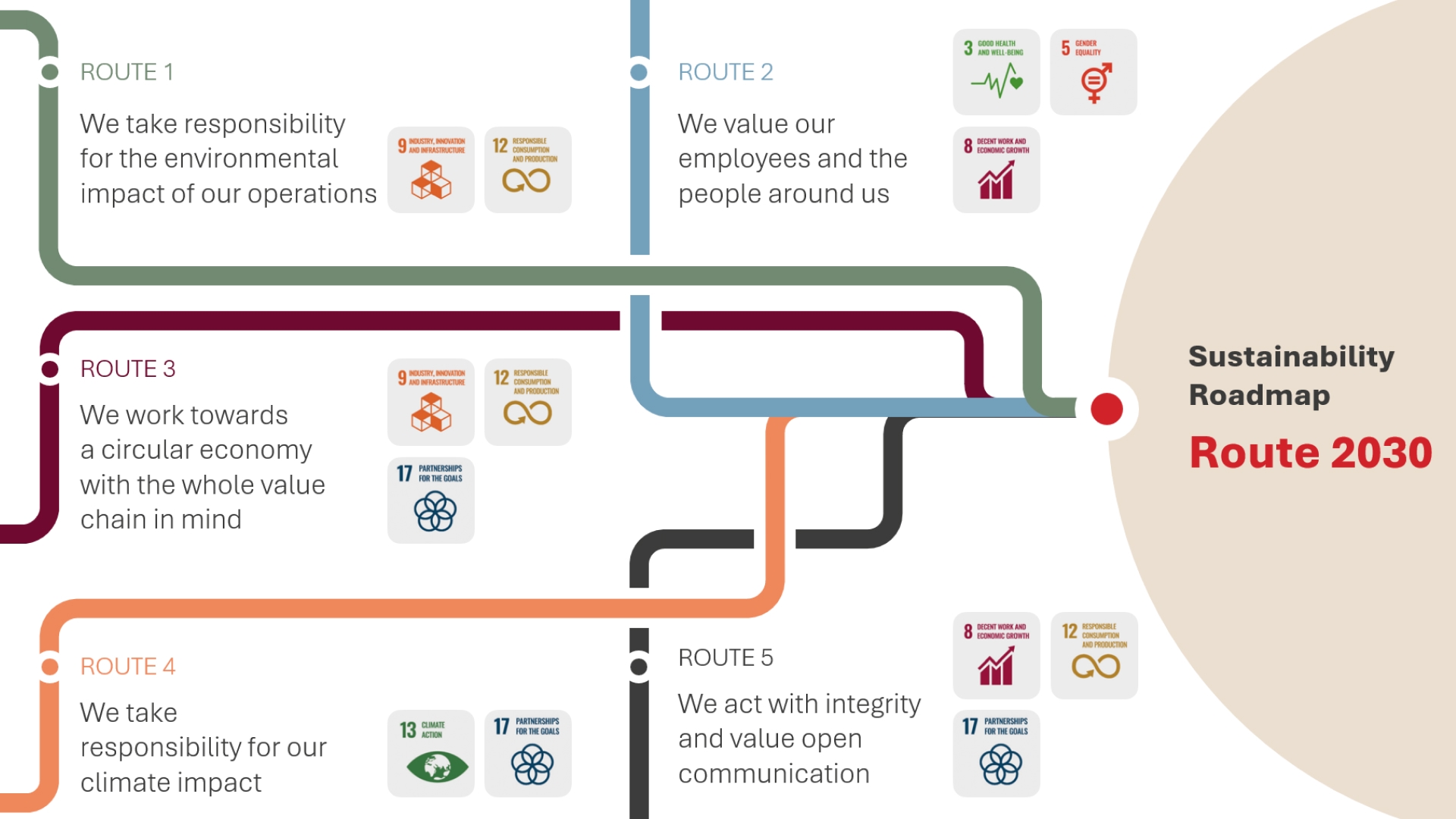

Our efforts align with Beaulieu International Group’s broader sustainability roadmap, known as Route 2030. Within this roadmap, we work together on 5 different areas leading to a zero footprint future:

At Distriplast, the imperative of a sustainable future is emphasized, with the belief that it must be collectively shaped by all employees.

This involves reshaping processes, behaviors, and societal norms, aiming for less energy, water, and waste consumption while ensuring safety and ethical sourcing.

And we believe everyone at Distriplast can contribute! Everyone is a reshaper!

For many years, Distriplast has been actively reducing its carbon footprint and seeking innovative ways to maximize material use.

We collaborate with you to optimize designs, so you can maximize your material use, lowering both environmental impact and project costs.

Distriplast encourages the recycling of materials by integrating a dominating share of re-ground PP. We can discuss repurchasing your clean PP corrugated sheet cuttings -100% pure without other materials—compacted in bales by full truck. This closed-loop system ensures valuable material finds a new life in more sustainable sheets.

Switching from single-use to reusable packaging is a cornerstone of a circular economy. It not only lessens plastic pollution but can also boost brand loyalty and reduce long-term costs. Distriplast’s PP corrugated boards are ideal for developing robust, multi-trip packaging systems—keeping materials in circulation at their highest value.

We’re eager to partner with you on:

1. Waste management & sorting – Improving how off-cuts and scraps become valuable material sources.

2. Incorporating recycled materials – Co-developing / Formulating the right balance of virgin and recycled PP.

3. End-of-life strategies – Developing reclamation and post-consumer loops to close the material cycle.

Whether you’re interested in reducing your carbon footprint with recycled plastic sheets or exploring new circular economy partnerships, our team is here to help.

For many years, Distriplast has been actively reducing its carbon footprint and seeking innovative ways to maximize material use. We invite our customers to join us in exploring circular economy strategies that create lasting value—together. We believe in a system where we eliminate waste and pollution, circulate products and materials at their highest value thanks to processes like maintenance, reuse, refurbishment, remanufacturing and recycling.

At Distriplast, this approach translates into a Reduce–Reuse–Recycle philosophy, ensuring polypropylene (PP) corrugated sheets serve as both a sustainable and efficient packaging, protection, or display solution.